“I want people to experience the emotional sensations that architecture can evoke through its spatial, structural and artisanal complexity: architecture on the wrist. That is why our watches are called after the architectural ornament”

Michiel Holthinrichs, founder of Holthinrichs Watches.

Our story

Our goal is to create such powerfully designed timepieces that people experience the emotional sensations that architecture can evoke through its spatial, structural and artisanal complexity: architecture on the wrist.

It is our deepest belief that this can only be achieved when we let our design philosophy flow through to even the smallest details of the design: when all components work together without concessions in what becomes a true integral design. This has been Michiel’s dream from the start: the ultimate three-dimensional wrist sculpture.

With pride, we announce the outcome of that dream: ORNAMENT NOUVEAU. A project we’ve been working on since 2017. It contains our first in-house movement in a spectacular, unprecedented sculptural design language.

A Dutch-made, in-house developed movement: a novelty for both us and the Netherlands!

Inspiration

The inspiration for ORNAMENT NOUVEAU is drawn from Art Nouveau and Early Modernist architecture.

Eugène Viollet-le-Duc, inventor of the Art Nouveau, used modern technologies to slim down constructions and reshape the principles in architecture. This meant the beginning of steel structures and spectacular spatial design. Modern architecture was born.

Victor Horta started working at a blacksmith at the age of 14. He knew the techniques and materials he worked with from the heart, and knew exactly how to form them, and implement them in a completely novel and organic way. He was so dedicated to the integration of design on all scales, that he even designed the clothing of his wife to match with his house.

The designer needs to know the properties of the materials, and the techniques to process them through-and-through in order to realize the best designs. All components and all scales need to follow a strict design language, a strict concept, to realize a whole and coherent design. Every component needs to get the same attention in all stages, from design to manufacturing and finishing. All components need to be exceptional on their own, and together forming a higher stage of beauty. Beauty is the result of strict design doctrine, aesthetic talent, well thought out proportions and exceptional craftsmanship.

Horlogerie Brut

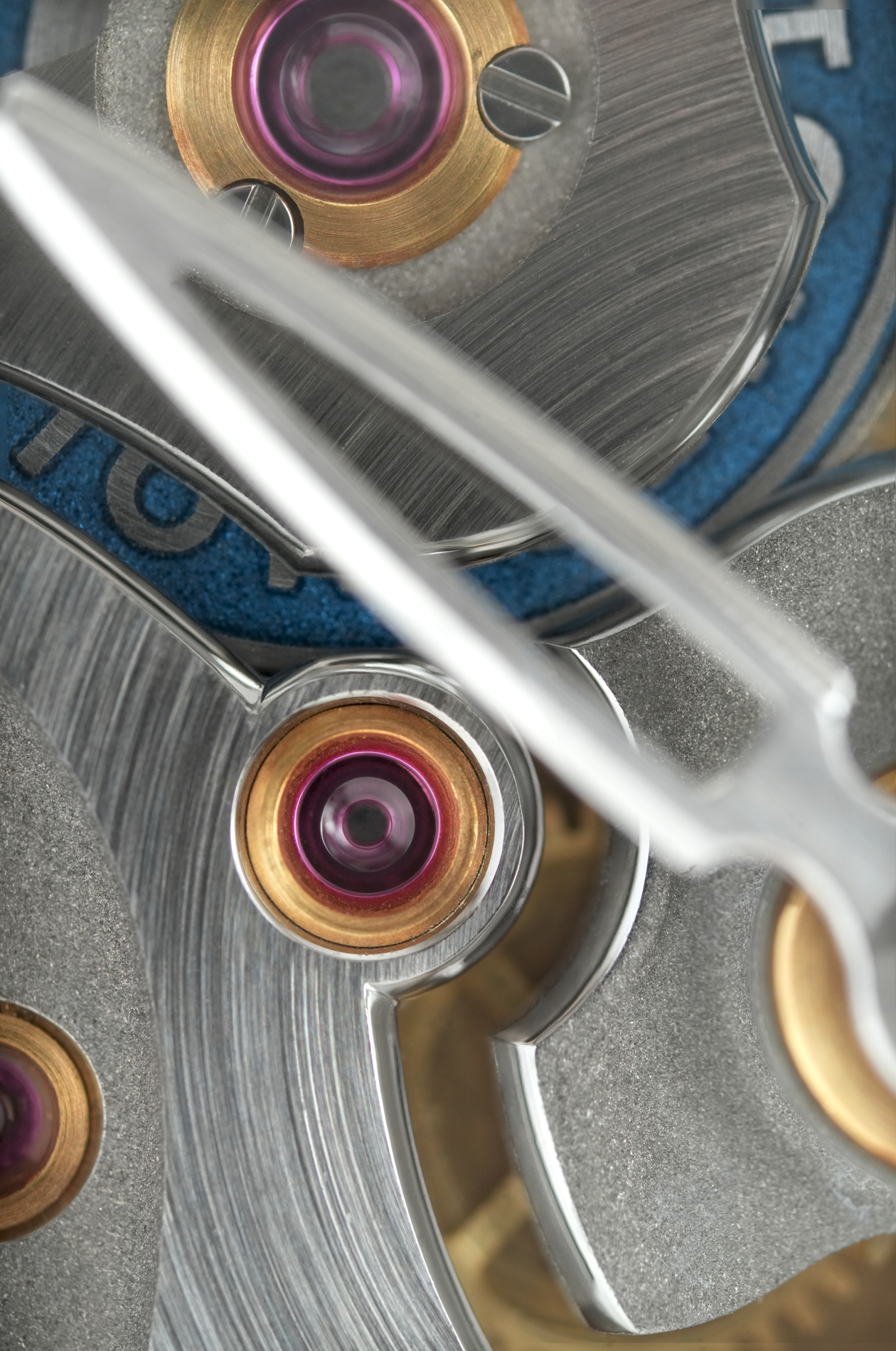

Parts of the case are intentionally left unfinished to showcase the process of the making as part of the aesthetic of the design. This is according to our modernist concept of “Horlogerie Brut” (coined from Le Corbusier’s Béton Brut). The concept stands for the use of heavy textural play, material honesty, natural patinas and RAW aesthetics directly derived from the manufacturing processes, combined with contrasting refined manual finishing. ORNAMENT NOUVEAU’s case is made out of titanium, providing sufficient strength for the thin lines of the lugs, and offers possibilities for customizations with selective surfaces anodized in several colors.

A fully integrated design

Every aspect of ORNAMENT NOUVEAU is designed to be an individual art piece as well as an integral part of the design as a whole. [hierop verder uitbreiden]

1. A unique titanium 3D-printed case

The case stands out by its unique and innovative design, instantly recognizable by its exceptional double curved surfaces that dynamically float from the lugs all around the caseband. Its organically shaped lugs are inspired by both Art Nouveau and nature, and connected to the case’s main body in a spectacular way. Organic, openworked structures that we could only achieve by using the latest innovations in high-end 3D metal printing. ORNAMENT NOUVEAU’s unprecedented design is intended to stir-up the possibilities of modern design in watchmaking. A three-dimensional sculpture meant to make the viewer wonder how it is formed.

The extensive process of 3D printing is highly complex: first the printing chamber is filled with titanium grade 5 particles all very uniform in size. Layers of 50 µm are formed by a nozzle adding a binder to the powder. To form all the layers of a single case takes up to 24 hours. Afterwards, the object needs to get sintered at about 1300 degrees Celsius, a process in which binder dissolves and the metal fuses together forming the case of the watch. The process is delicate and error sensitive. Each model needs to be carefully checked and measured to make sure it is within the required specifications.

Once passed QC, we still need to CNC mill the fittings for the caseback, movement and crystal before the complex sculpted shapes can proceed to the final stage of extensive selective manual finishing. This final finishing, because of its intricate shapes, can only be processed by hand and takes a full week of filing and brushing to bring out the beauty of the design.

2. Our first manufacture movement

ORNAMENT NOUVEAU features our first in-house developed movement in a spectacular, unprecedented sculptural design that fully reflects the overall design language of the watch. A dream come true, and the only way to realize our vision of fully integrated designs.

Creating this movement is a huge step for both us, and the Netherlands. A caliber that is developed, finished and assembled, as well as largely manufactured in the Netherlands. Crucial in this development is the relationship we built over the years with a local precision manufacturer near Rotterdam that is used to make highly specialized micro tools for medical purposes. Over the years that we collaborated, he followed our development, and once we decided to commence on this project, he accepted the challenge of manufacturing the ébauche parts. Our goal is to build a Dutch manufacturing ecosystem for locally produced movements, acting largely independent from large suppliers in Switzerland, and contributing to the realization of a local watchmaking industry.

The movement, though simple in its functioning – telling only the hours and minutes -, is complex in its execution. While only 4mm thick, it offers maximal three-dimensionality through complex machining and extensive manual finishing. The mainplate of the movement consists of a double concave shape, creating a strong optical three-dimensional effect. The mainplate is made out of brass, and available in four galvanic colors: 18K gold, 18K rose gold, white rhodium or black rhodium. From the sides of the mainplate, attached with hidden screws, organically shaped stainless steel bridges are cantilevered above the center of the movement. Each of them executed as miniature sculptures with multiple interacting three-dimensional surfaces and manually finished with heavy contrasting textures and anglage for maximal visual depth.

The star of the show is our in-house developed variable inertia balance wheel. A dynamically shaped openworked circle held in place in an exceptional three-dimensional glass bridge (called the “Holthinbridge”).

3. Our novelty eclipse dial

Central in the movement, a specific cast-iron like object bridge features a screwed down nut created to fix the dial we uniquely developed for ORNAMENT NOUVEAU. A dial made of UV-sensitive photochromic material, a novelty in the industry. The dial turns smoked black in UV lighting, protecting the oils in the skeleton movement from degradation in UV light, as well as providing a playful aspect to the watch. When inside, one can see the beautiful sculptural movement, while outside in daylight the watch turns into a very classical timepiece, subduing the inner mechanics and emphasizing the sculptural case.

4. Strap

With the conception of ORNAMENT NOUVEAU and its three dimensional shapes, it was obvious to us that this model needed an exceptional strap to complete the whole concept. Nothing else other than nature can emphasize our strive for organic design more, so it was immediately clear to Michiel that the strap had to be crafted out of the – often overlooked – but most beautiful part of the noble alligator creature: the tail. Its superb scales can bring an unprecedented depth and a sense of luxury. It is very tough and thus a very difficult material to work with. We selected three ateliers we highly respect for their beautiful workmanship, resulting in one unparalleled result.

5. Presented in a unique sculpture

Uniquely for ORNAMENT NOUVEAU, we created a playful and light openworked art piece that acts as an abri to embrace and reflect the delicate and complex design of ORNAMENT NOUVEAU, and its clear architectonic inspiration. It is composed as an interplay of laces that organically float around the timepiece in a dynamic way.

We crafted the sculpture out of solid stainless steel in the same innovative spirit as the watch itself. This time by using selective laser melting, another high-end 3D printing technology. The sculpture acts as both an object of art and as a way to present ORNAMENT NOUVEAU in the most elegant way, covered by a protective, hand blown glass dome. The sculpture can be commissioned to accompany the timepieces by both clients and retailers.